As industrial automation gains momentum across South America, manufacturers are increasingly seeking compact, high-performance rotary transmission solutions that ensure seamless power, signal, and pneumatic flow across rotating structures. From rotary tables and robotic arms to packaging and testing machinery, slip rings play a vital role in maintaining continuous communication between moving and stationary parts.

JINPAT Electronics, a global slip ring specialist, has launched several new models tailored for automated systems operating in diverse environments and tight spaces—common challenges for South American industries. These innovations offer enhanced reliability, modularity, and integration capability, while helping reduce maintenance downtime and overall equipment costs.

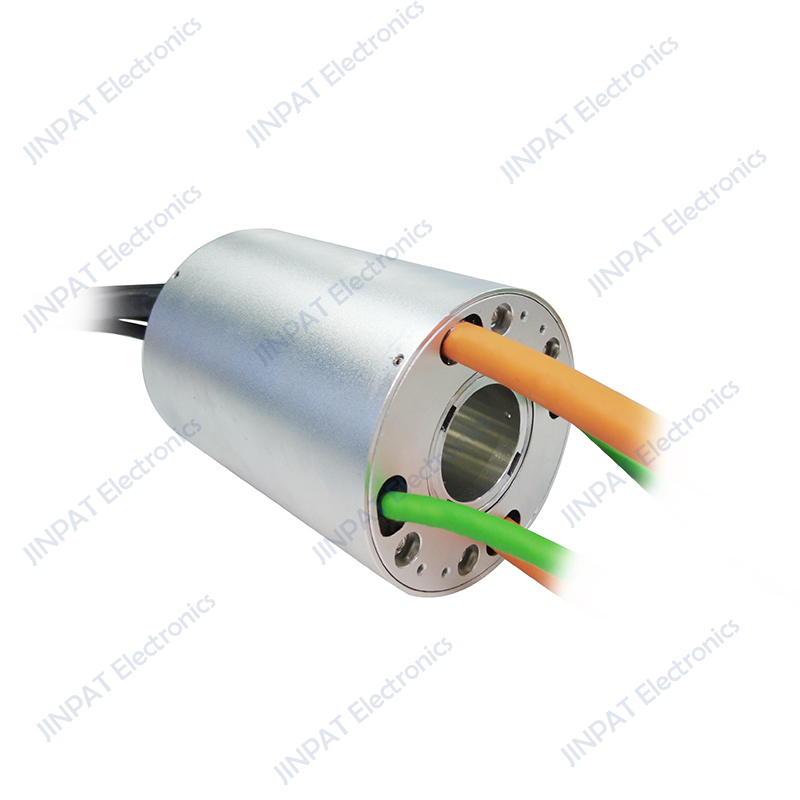

JINPAT’s high-performance through-bore slip ring built for complex industrial automation systems. With a 38mm center hole, an overall diameter of 99mm, and a length of 131.7mm, this model is engineered for applications requiring simultaneous transmission of power and sensitive signals. It supports 8 circuits of 15A current, 16 channels for encoder signal transmission, and 3 shielded signal lines, all enclosed in a housing with conductive white anodized surface treatment—enhancing EMI shielding and signal stability. Designed to operate within a temperature range of -20°C to +60°C and rated at IP50, this model is ideal for signal-sensitive automation platforms and motion control equipment.

For applications prioritizing cost-efficiency and modular customization, the SPT050-104-1210 model offers a smart solution. Featuring a plastic injection-molded structure, this slip ring is significantly lighter and more economical than traditional models, while still delivering strong performance. The main shaft and brush holder are designed to be separable, allowing for flexible adjustment in terms of length and circuit count based on application needs. It operates at speeds up to 400 rpm, handles voltages up to 500VAC/DC, and performs reliably in temperatures as low as -40°C—making it suitable for a wide range of mid-speed, mid-power industrial applications.

In environments where both electrical and pneumatic transmission are required within a confined space, JINPAT slip ring stands out with its integrated structure. This multifunctional slip ring allows for the simultaneous transfer of electrical power and compressed air, simplifying mechanical design and improving system integration. It’s particularly well-suited for industrial robots, rotary actuators, and compact automation systems where space-saving and operational reliability are top priorities. The integrated design helps minimize signal interference and external environmental impact, ensuring stable operation even in demanding scenarios.

These newly developed slip rings reflect JINPAT’s commitment to serving global markets with localized solutions. Their adaptability to South America’s diverse industrial landscape, whether in high-humidity coastal areas or high-altitude production zones, make them ideal for the region’s evolving automation needs.

Contact us today to explore customized slip ring solutions tailored to your medical application.